October 30, 2023

Laser engraving: principles, advantages, and applications!

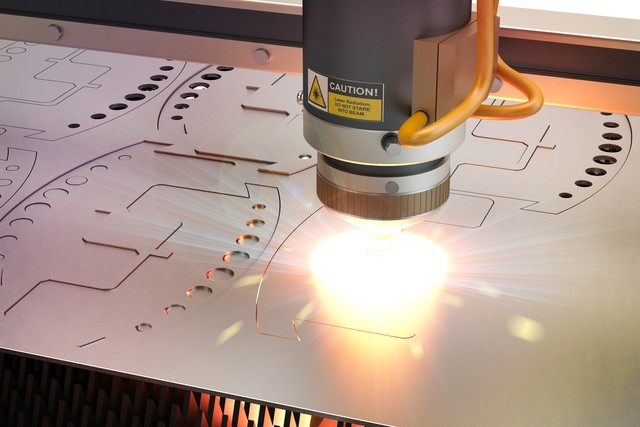

Within the field of IT for precision machining in modern Chinese enterprises, laser engraving shines as a standout technique. It utilizes a laser beam to heat and vaporize the surface of a workpiece, effectively eliminating material. Compared to traditional production methods, laser engraving boasts numerous advantages including enhanced efficiency, precise outcomes, and environmental sustainability. As a result, its use has gained momentum in domestic industrial production, providing convenience and groundbreaking advancements across various industries. This piece will explore the complexities of laser engraving and its widespread implementation in industrial settings.

To better understand laser engraving, we need to understand some basic terms first. The technology uses a laser beam of a specific wavelength to irradiate the surface of the material to melt the material, and at the same time the laser beam is heated to a certain power level to cause the material on the surface of the material to vaporize, vaporize or ablate, so the material is removed.

During laser engraving, the focal point of the laser beam is crucial. By concentrating the light into a tiny spot, the laser beam can illuminate the material with precision. As the laser energy increases, ablative holes are formed on the surface of the workpiece, resulting in gasification, vaporization, melting, and other changes. The ablative holes will form as the laser energy increases. Once sufficient holes have formed, further processing can begin.

The advantages of laser engraving over traditional processing methods are obvious:

Laser engraving machines are fast, efficient, and easy to use. Laser engraving machines require no auxiliary tools, and the working process is extremely rapid.

Laser engraving precision requirements are extremely high, suitable for a variety of different and materials engraving, ensuring product quality.

Additionally, it is pollution-free, does not produce exhaust gases, and is environmentally friendly.

Laser engraving is also highly adaptable to a wide variety of materials, including wood, plastic, paper, leather, and so on.

Regardless of the material of the workpiece, laserpecker 12 laser engraving machines can handle metal and other materials easily.

Laser engraving has become an integral part of domestic industrial production,laserpecker metal engraving with its applications extending to various fields, including electronics, plastics, and metals. This technology offers a precise method for marking electronic products without causing harm to components, resulting in cost savings and improved quality. In the realm of plastic production, laser engraving has proven to be an efficient solution for creating mold parts. Similarly, in metal manufacturing, it provides a reliable means for cutting and drilling different metal plates with ease.

Due to the development of laser engraving technology, two types of laser engraving have been developed. The material is cut directly using a variety of precision machine tools to achieve non-contact processing with extremely high precision requirements, but the main focus of the research is on a variety of structural metals with a thickness of less than 0.5mm.

The development of laser inner glass carving technology has led to a new type of glass art

Engage art students with Chinese laser - laser engraving

You can learn more about laser engraving's future by reading the following information!

Posted by: shiftsd at

03:41 AM

| No Comments

| Add Comment

Post contains 529 words, total size 5 kb.

35 queries taking 0.0941 seconds, 61 records returned.

Powered by Minx 1.1.6c-pink.